Our trades

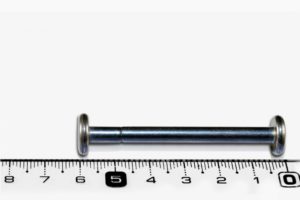

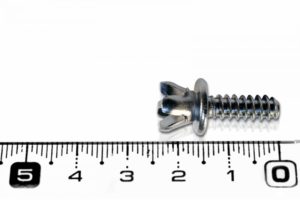

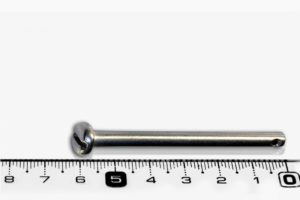

BMB specializes in special bolts and the manufacturing of all assembly parts whatever the sector of activity.

The core of our business is cold forming, a process that allows great flexibility in the production of simple or complex forged parts, to our customers’ configurations and measurements, the transformation of your turned parts to a technique adaptable to cold forming, but also reworking by continuous rolling for the formation of threads or other shapes such as grooves, knurling, break rings etc.

In addition, our very short manufacturing cycles allow us to respond to urgent requests and specific orders as quickly as possible.

Our know how

Industrial screw productivity:

With a capacity of 17 million parts monthly, BM-B can produce any industrial fastener part, or assembly part in small and large series.

Cold forming is an innovative manufacturing process:

BM-Boulonnerie is in a position to develop, with its design office, any new special bolt parts from plans, in partnership with its customers and also turned parts able to be produced by cold forming for cost reductions. Trust us with your projects, we will bring you the solutions best suited to your needs.

Special bolts design office:

Development and fulfilment of all your assembly parts by cold forming.

All metals and alloys:

Steel, Brass, Ferritic stainless steel, Food grade stainless steel, Special stainless steel, Aluminium, Arcap copper alloy, Maillechort copper alloy, Copper etc.

All treatments HT – ST

Industrial screw part logistics:

Large storage capacity letting customers call for supplies.